A high background is one of the most common quality control issues encountered during the process of western blotting. When a high background occurs, it can be very difficult to distinguish the relevant data from the irrelevant data. A uniform high background can be caused by numerous issues and may take some work to resolve -- but without resolving the situation, the blot may not be readable.

A high background is one of the most common quality control issues encountered during the process of western blotting. When a high background occurs, it can be very difficult to distinguish the relevant data from the irrelevant data. A uniform high background can be caused by numerous issues and may take some work to resolve -- but without resolving the situation, the blot may not be readable.

Ensuring that Buffers Aren't Contaminated

A contaminated buffer can easily lead to a high background during a western blot. Most commonly, a contaminated buffer will occur due to the presence of bacteria -- but there can be other contaminants as well. When contaminants are introduced into the buffer itself, they will impact the entirety of the blot, including the background. The only way to resolve this type of interference is to completely replace the old buffers.

Making Sure the Procedure Is Completed Properly

Another issue that can cause a high background is a failure to follow proper procedure. Poor membrane handling, membrane overexposure, and insufficient washing can all cause a high background. These issues will need to be resolved through proper processing. Poor handling of the membrane generally occurs when the membrane dries out. The membrane can dry out if it's not properly hydrated using the right chemical; typically methanol.

Membrane overexposure can also be an issue -- but it's very easily resolved. All that has to be done is expose the membrane for a lessened amount of time. Likewise, insufficient washing simply requires that the washing be completed more thoroughly. Washing is required to remove an excess of antibodies. When there are too many antibodies present in the blot, it is difficult to distinguish from the background. Improved washing can also be implemented through the use of better washing solutions.

Removing Insufficient Blocking

Without the right blocking, western blots cannot be easily read. Insufficient blocking generally occurs because of problems during incubation. If the incubation time isn't long enough, the right areas won't be blocked. If the temperature of the incubation is not correct, the blocking will also not be completed. There are also chemicals that can be added to the process to further improve blocking.

Ensuring the Compatibility of Blocking Agents

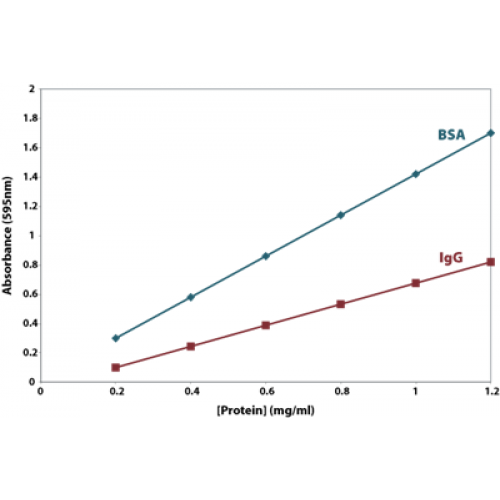

Blocking agents, like other products used throughout the blotting process, have to be tailored to specific applications. Using the wrong blocking agent can easily cause interference and a poorly distinguished blot. Some blocking agents are sera protein-based, while others are protein-based. Different antibodies can potentially interact with the blocking agents, making it necessary to find the most suitable agents possible. Protein free blockers are one of the best and easiest solutions.

Reducing the Concentration of Antibodies

A generally high concentration of antibodies may also cause a high background. Because the antibody concentration is so high, the entire membrane will be coated with it. This will make it very difficult to determine anything conclusive. When it comes to a high concentration of antibodies, there are really only a few solutions. The antibodies can be properly washed or a lower saturation of antibodies can be utilized throughout the process. The membrane may also need to be properly treated -- so that it is not overly dry -- so it doesn't absorb too much of the antibody solution.

High backgrounds can additionally occur when the chemicals and supplies are either ill-suited to the task or of a low quality. High backgrounds are additionally only one of a myriad of issues that can occur throughout the western blot.

Other factors to consider and have been discussed before are the choice of membrane: PVDF or Nitrocellulose - Which Membrane is Best?. An often overlooked issue with membranes is their shelf life. Before using a membrane, make sure that it has not expired and has been stored correctly.